2022-04-27

2022-04-27

2022-04-27

详情

◆传动功能一应用领域

Transmission function application area

GDXR/BR系列斜齿轮减速器电机是参照摆线针轮减速机的安装尺寸设计的:由YE3系列电机、斜齿轮组成的新型减速传动装置,该产品具有高精度、高效率、传递力矩大、可靠性强等显著优点。根据要求可进行任意位置卧式或法兰安装,拥有多样的附件功能。广泛适用于各种低速驱动的机械设备,是机械传动的通用基础件。此外根据用户要求,配装防爆电机、制动电机、变频电机等特殊电机。

GDXR/BR series helical gear reducer motor is designed with reference to the installation size of cycloidal pinwheel reducer: a new type of reduction transmission device composed of YE3 series motor and helical gear, this product has high precision, high efficiency, large transmission torque, Significant advantages such as strong reliability. It can be horizontal or flange mounted in any position according to requirements, with various accessory functions. It is widely used in various low-speed driven mechanical equipment, and is a general basic part of mechanical transmission. In addition, according to user requirements, special motors such as explosion-proof motors, brake motors, and variable frequency motors are equipped.

◆GDXR/BR系列斜齿轮减速电机的技术特点

◆Technical features of GDXR/BR series helical gear reduction motors

1、齿轮传动采用高精度硬齿面齿轮;

Gear transmission adopts high precision hardened gear.

2、低噪声,运转平稳

Low noise, smooth operation

3、承载能力强,温升低,使用寿命长

Strong bearing capacity, low temperature rise and, long service life.

4、传动比分级精细,范围i=2~28800;

The transmission ratio is precise and the range is i=2~28800;

5、设计精巧,结构紧凑,体积小,安装简便

Designation is ingenious, Structure is compact,Volume is small,Installation is simple.

6、GDXR/BR系列是在模块组合体系的基础上设计的,可与不同的传动附件组合,满足不同的传动结构方案

GDXR/BR series is designed on the basis of modular combination system, and can be used withdifferent transmission accessories combination .To meet different transmission structure schemes.

带筋的高刚性铸铁箱体,齿轮采用优质高强度台金钢,表面渗碳硬化处理,经过精密加工,确保轴平行度和定位精度,这一切构成了齿轮传动的完美结合

High rigid cast iron box with ribs, gears made of high quality and high strength platen steel, surfacecarburizing and hardening treatment, through precision machining to ensure shaft parallelism And positioningaccuracy, all of which constitute the perfect combination of gear transmission.

◆型号(规格)的确定(必须满足条件fs> fa)

Determination of model (specification) (must meet the condition fs>fa)

1)电机与减速器直联或通过连轴连接;

a.在选型参数表中找到相应的电机功率、极数。

b.在此功率和极数下,初步选用一个具有相近传动比的机型,并记录下其使用系数(f。

c.比较,若满足条件f>fA,则就是可用机型。否则,加大机型,直到满足条件。

2)电机与减速器之间具有前置减速联接

如电机与减速机之间通过齿轮、皮带、链轮等减速装置联接,由于输入转轴的增加,须把电机功率折算到减速机输入轴上,即把电机的功率乘以前置减速装置的传动比。用折算的功率,按前述( 1 )中的方法选取。此时,仍要注意电机数不变。

1) The motor and the reducer are directly connected or connected through a connecting shaft;

a. Find the corresponding motor power and number of poles in the selection parameter table.

b. Under this power and number of poles, initially select a model with a similar transmission ratio, and record its use coefficient (f.

c. Compare, if the condition f>fA is satisfied, it is the available model. Otherwise, increase the model until the conditions are met.

2) There is a front deceleration connection between the motor and the reducer

If the motor and the reducer are connected by gears, belts, sprockets and other reduction devices, due to the increase of the input shaft, the motor power must be converted to the input shaft of the reducer, that is, the power of the motor is multiplied by the transmission ratio of the front reduction device. . Using the converted power, select it according to the method in (1) above. At this time, it is still necessary to pay attention to the constant number of motors.

◆ 径向载荷检验

Radial Load Inspection

减速机轴头装有齿轮、皮带、链轮时,将产生较大的径向载荷。此时,必须进行径向载荷检当方法见选型参数释义中有关内容。若径向载荷超出许用值,可选用更大规格机型。

When the shaft head of the reducer is equipped with gears, belts and sprockets, a large radial load will be generated. At this time, the radial load inspection method must be carried out, see the relevant content in the explanation of the selection parameters. If the radial load exceeds the allowable value, a larger size model can be selected.

◆ 径向力校核

Radial force check

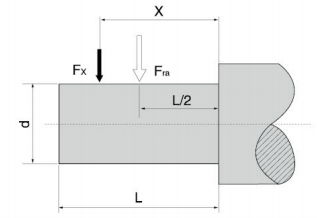

实际作用点不在输出轴轴伸中间时,需要下述公式对选型表中的许用径向力值进行计算

When the actual action point is not in the middle of the shaft extension of the output shaft, the following formula is required to calculate the allowable radial force value in the selection table.

当0≤X

当X=L/2时FX=Fa[N]

当L/20

FRa--选型表中给出的许用载荷( 作用在X=L/2处)

FX --实际作用点的许用径向载荷

X--样本中轴肩到载荷实际作用点的距离

L--输出轴轴伸长度(本样本中给定的长度,参照外形安装尺寸图表)

工作元件的实际径向载荷Fr,与实际工况系数FA的乘积不得大于实际作用点的许用径向载荷Fx,即: FA*F,≤Fxo

When 0≤X

FX=Fa[N] when X=L/2

When L/20

FRa--The allowable load given in the selection table (acting at X=L/2)

FX -- Allowable radial load at the actual point of action

X--the distance from the shoulder in the sample to the actual point of application of the load

L--shaft extension length of output shaft (the length given in this catalog, refer to the outline installation dimension chart)

The product of the actual radial load Fr of the working element and the actual working condition factor FA shall not be greater than the allowable radial load Fx at the actual action point, namely: FA*F, ≤ Fxo

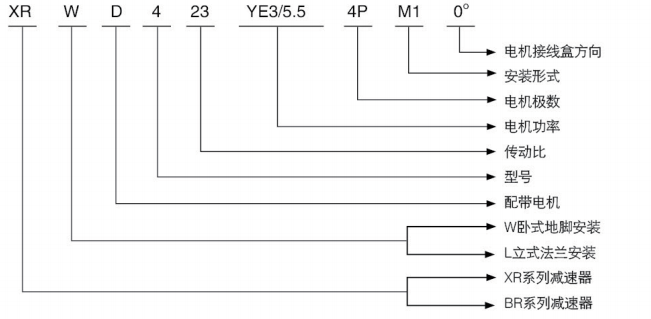

◆ 型号表示方法

Model indication method

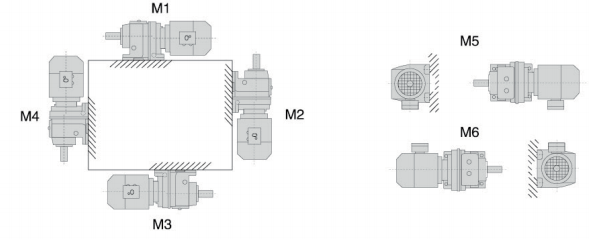

◆ 安装型式图例

Installation type legend

安装位置说明:减速电机有M1...M6共6种安装位置。

Installation position description: There are 6 installation positions for the geared motor, M1...M6.

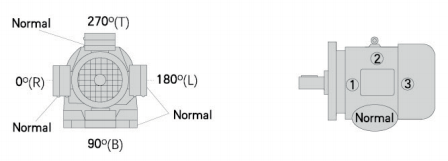

◆ 电机接线盒和出线口位置

Motor Terminal Box and Outlet Locations

电机接线盒从电机风扇罩着(如图),位置分别表示为0°,90°, 180°或270°

出线口的位置也可以进行选择(如图),分别表示为“Normal”“1”“2”或“3”。

The motor junction box is shielded from the motor fan (pictured) and the positions are indicated as 0°, 90°, 180° or 270°

The position of the outlet can also be selected (as shown in the figure), which are respectively expressed as "Normal", "1", "2" or "3".

上一页